December 15, 2025

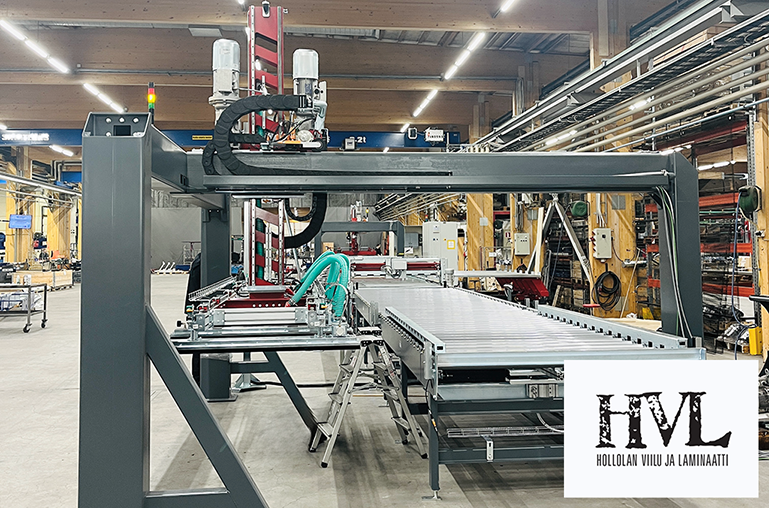

We have cooperated with Hollolan Viilu ja Laminaatti Oy before, as we delivered pressing line equipment to the company a couple of decades ago. Our cooperation was continued and we designed a new similar pressing line for panel production together. The new line is more automatic than the first one, and we have also paid more attention to ergonomics. Our delivery includes de-stacking equipment, disc conveyor, automatic pulling device and vacuum box gripper. The line has been delivered to the customer, the installation work will be completed in early December, and commissioning will start in December.

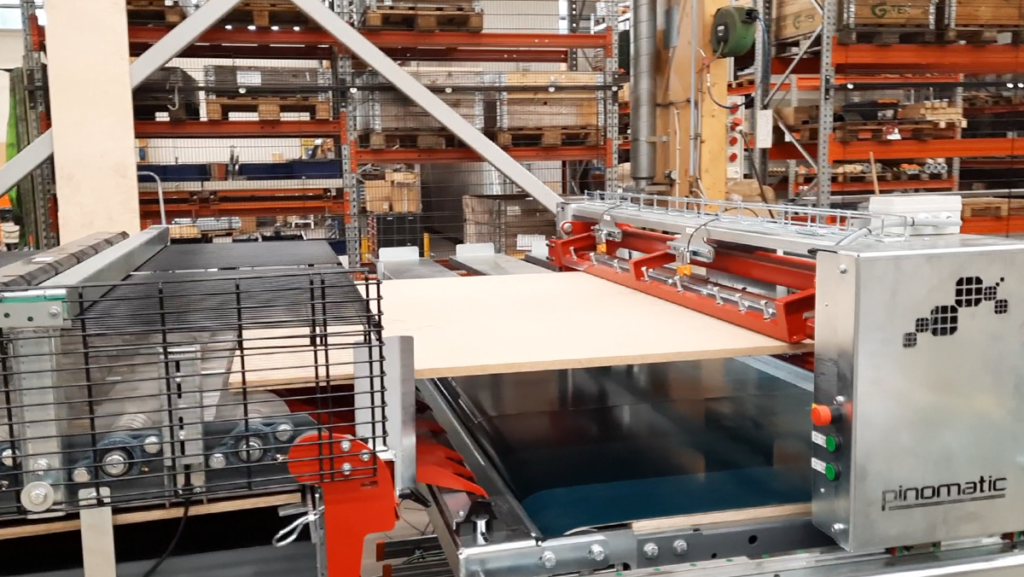

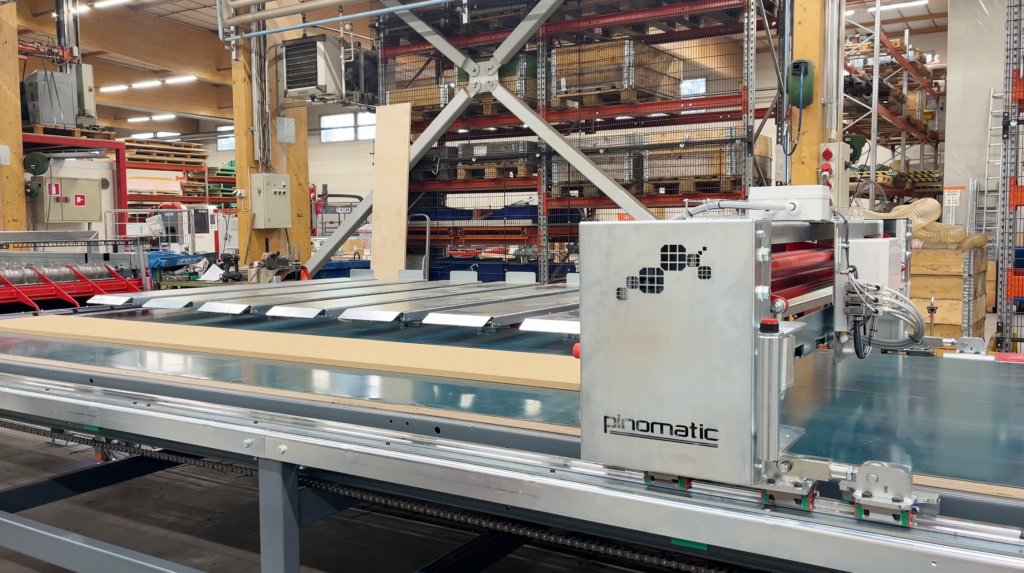

The new line features a rotating disc conveyor after the glue applicator, which cleans the glue from the discs, and a pulling device, which automatically pulls the panel into the correct position on the veneer that awaits glueing on the stacking table. Once the veneer is glued underneath the panel, the forks bring the veneer onto the panel, after which the operator aligns the panel and the forks retract, dropping the veneer onto the panel. Next, the panels continue to the press for final pressing. The conveyor takes the veneered panels to the vacuum box gripper, which lifts and stacks the finished panels into bundles. The new line can handle larger quantities of sheet products, increasing production capacity and efficiency.

The company manufactures semi-finished carpentry products in a customer-oriented and tailor-made manner to the desired degree of completion. It also delivers ready-to-install sheet products, from veneer panels to high-pressure laminates.

Read more about HVL Oy at https://hvloy.com/

Photos from Pinomatic’s production facilities during FAT testing.